Box Part 1... and stuff

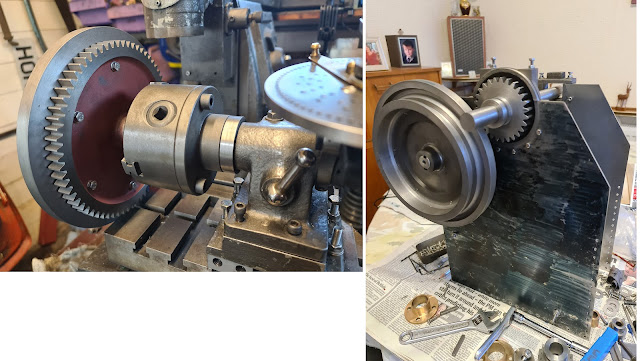

Following the back of the casting now being fully machined, I'm working to a true datum, the previous roughing cuts can be finally machined to size. Using the previous drilled and tapped holes to hold it onto the face plate from behind, this will enable me to machine the inside without fear of catching any bolts or fixings.

This part has been a tricky but well thought out machining process, mainly because of the size of it, and also the need to hold it in a chuck or face plate to make a start on it.

I have also just ordered a Gear shaft Bracket , Part Number 81153 for the Burrell. This will be cast as they do not currently have one in stock but as its not needed right away I have time for it to arrive.

<< Left is the pattern that will be used for this casting, this is from the foundry and most of the parts, I ask for a photo of the bit before ordering, as mistakes sometimes occur when ordering from a part description.

I recently visited a show and there was a very impressive Black 5 being readied for its turn on the track. I took a photo, the smell from the coal and the work that had gone into making an engine of this size was very impressive. Occasional visits to shows helps to spur you on, and talking to one of the club members always ends up with an idea or two.

Just a small update on the Solar charge controller I bought to add to my setup for safety reasons.

The next post may be a while as the teeth cutting I know will take many weeks to complete, and then we will be onto the bearings, and hopefully the gear change bracket will be with us in the post.

Until then stay safe ; make swarf; have fun!

Stephen.

Comments

Post a Comment